|

Fundamental Research in Membrane Separations

-

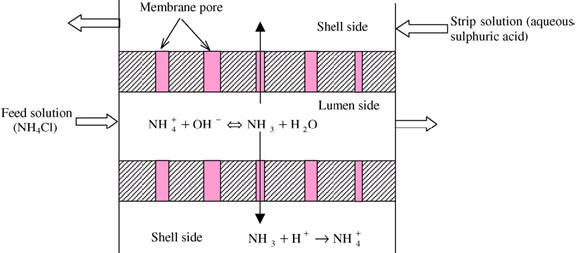

Membrane

Contactor as Degasser: simulation studies

Membrane contactor as degasser

(from

water) can be either

operated under vacuum or under LLE modes. Numerical

simulations of mass transfer under different flow

conditions have been attempted in order help to design

the hollow fibre (hydrophobic polymer) based membrane

contactor. Mathematical models have been developed* by

using the resistances-in-series mass transfer system

that takes into account boundary layers, membrane

porosity, phenomenological considerations and mass

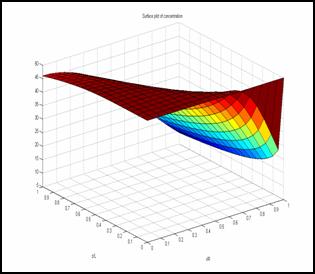

balances of the membrane contactor. Simulation result

shows the variation of concentration in both axial and

radial direction.

*

Amish Mandowara and Prashant K. Bhattacharya, “Membrane

contactor as degasser operated under vacuum for ammonia

removal from water: A numerical simulation of mass

transfer under laminar flow conditions”, Computers

Chem. Eng. (DOI information:

10.1016/j.compchemeng.2008.12.005).

-

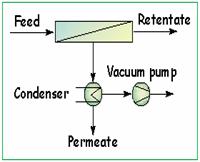

Pervaporation:

membrane casting, separations and modelling

Pervaporation using hydrophobic membranes were observed

to be promising for streams such as water contaminated

with VOC's, organic-organic solutions, etc.

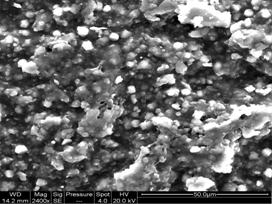

Membrane Casting:

Several polymeric hydrophobic and hydrophilic dense

membranes* were cast, modified and characterized

through FTIR, XRD, 1H NMR, SEM, AFM, etc. Specific systems like

hydrazine-water, alcohol-water, organic-organic, etc.

have been studied. They were also assessed in comparison

to commercial membranes for several typical chosen

mixture separations.

*

S. V. Satyanarayana, A. Sharma and P. K. Bhattacharya,

“Composite membranes for hydrophobic pervaporation:

Study with toluene-water system“, Chem. Eng. J., 102,

171 -184 (2004).

* S. V. Satyanarayana, P. K. Bhattacharya,

“Pervaporation of Hydrazine Hydrate: Separation

characteristics of membranes with hydrophilic to

hydrophobic behaviour“, J. Membrane Sci., 238,

103 -115 (2004).

* Mrinal K. Mandal and P. K. Bhattacharya, "Poly

(ether-block-amide) membrane for pervaporative

separation of pyridine present in low concentration in

aqueous solution", J. Membrane Sci., 286, 115-124

(2006)

* Mrinal K. Mandal and P. K. Bhattacharya, “Poly (vinyl

acetal) membrane for pervaporation of benzene-isooctane

solution”, Separ. Purif. Technol., 2007, 61

(2008) 332–340.

Real coded genetic algorithm and

Model Development:

Models have been developed to predict partial fluxes

and selectivity's'. Real coded genetic algorithm has

been used to optimize process parameters.

* Gopal R. Nemmani, Satyanarayana V. Suggala and

Prashant K. Bhattacharya, “NSGA-II for Multiobjective

Optimization of Pervaporation Process: Removal of

Volatile organics from Water”, Ind. Eng. Chem. Res.

(in press).

*

Satyanarayana V. Suggala and Prashant K. Bhattacharya,

“Real Coded Genetic Algorithm for Optimization of

Pervaporation Process Parameters for Removal of Volatile

Organics from Water“, Ind. Eng. Chem. Res., 42 (13),

3118 -3128 (2003)

* Nazish Hoda, Satyanarayana V. Suggala and Prashant K.

Bhattacharya, “Pervaporation of Hydrazine – Water

through Hollow Fiber Module: Modeling and Simulation“,

Computers Chem. Eng., 30 (2), 202-214 (2005).

Roles of Permeant-Membrane Interactions:

The membrane permeation of a component followed by its

vaporization on the opposite face is governed by the

solubility and downstream pressure. We studied and

measured* the evaporative flux using dense membranes

with different free volumes and different affinities (wettabilities

and solubilities) for the permeant. Interestingly, the

evaporative flux for different membranes vanished

substantially (10-75%) below the equilibrium vapour

pressure in the bulk. The discrepancy was larger for a

smaller pore size and for more wettable membranes

(higher positive spreading coefficients). This

observation, which cannot be explained by the existing

(mostly solution diffusion type) models of pervaporation,

suggests an important role for the membrane-permeant

interactions in nanopores that can lower the equilibrium

vapor pressure.

*

A. Sharma, S. P. Thampi, S. V. Suggala and P. K.

Bhattacharya, Pervaporation from a dense membrane: Roles

of permeant – membrane interactions, Kelvin effect, and

membrane swelling, Langmuir, 20(2004), 4708.

Location of vaporization using single component

pervaporation:

A mathematical model* was developed assuming two zones

inside the membrane; namely, liquid permeation and vapour permeation zones. Considering a pressure

distribution across the thickness of the membrane, Kelvin

equation (saturation vapour pressure gets

modified inside the membrane due to permeant membrane

interactions) proved to be useful in developing the

model.

* Sumesh P. T. and P. K. Bhattacharya, “Analysis of

Phase Change during Pervaporation with Single Component

Permeation", Colloids and Surfaces A: Physicochemical

and Engineering Aspects, 290, 263–272 (2006).

Positron annihilation study of pervaporation dense

membranes*:

Determination of free volume sizes is crucial to the

understanding of pervaporation process. Positron

annihilation technique has been developed into a

powerful characterization tool for the study of free

volume and free volume fraction in polymers. Long-lived

components (lifetimes in the range 1.4 to 3 ns) were

found, which were attributed to ortho-positronium (o-Ps)

pick-off annihilations in free volumes. Free volume data

is used to interpret the data of hydrazine hydrate

separation by pervaporation.

*

S. V. Satyanarayana, V. S. Subrahmanyam, H. C. Verma, A.

Sharma, P. K. Bhattacharya, “Application of positron

annihilation: Study of pervaporation dense membranes“,

Polymer, 47, 1300-1307 (2006).

-

Development

of Predictive Models for Flux Decline

Osmotic pressure controlled (for low MW solutes) and

gel-layer controlled (for high MW solutes) flux decline

have been examined by several workers with regard to

modelling of UF flux behaviour. The applicability of

either of these models is questionable for all operating

conditions and solutes, especially in the intermediate

range of molecular weights. Several predictive models

have been developed overcoming these limitations.

The combined influence of osmotic pressure and gel-layer

on the flux decline is to be expected during UF with

solutes that display substantial osmotic pressure, and

in addition, either form a true gel or a 'pseudo gel'.

Such excellent models* can be useful for design purposes

of UF and RO.

* C. Bhattacharjee and P. K. Bhattacharya, “Prediction

of limiting flux in ultrafiltration of kraft black

liquor“, J. Membrane Sci., 72, 137-147 (1992).

* S. Ganguly and P. K. Bhattacharya, “Development of

concentration profile and prediction of flux for

ultrafiltration in a radial cross flow cell“, J.

Membrane Sci., 97, 185-198 (1994).

* S. De and P. K. Bhattacharya, “Flux prediction of

black liquor in cross-flow ultrafiltration using low and

high rejecting membranes“, J. Membrane Sci., 109,

109-123 (1996).

* S. Bhattacharjee, A. Sharma and P. K. Bhattacharya, “A

unified model for flux prediction during batch cell

ultrafiltration“,

J.

J. Membrane Sci,

111, 243-258 (1996).

-

Role

of Surface Interactions

The approach is to systematically incorporate the

intermolecular interactions between solutes and

membranes to develop models of flux decline. The role of

solute-solute interactions is manifested in the

variation of diffusivity and osmotic pressure, which

govern the transport of the solution across the

polarized layer and through the membrane. The

solute-membrane interactions further affect the

transport of solute and solvent through the membrane

pores, thus predicting adsorption, fouling, etc. Models,

thus, represent a marriage between the surface science

and membrane separations aspects, and provide excellent

agreement with experimental fluxes.

* S. Bhattacharjee, A. Sharma and P. K. Bhattacharya,

“Surface interactions in osmotic pressure controlled

flux decline during ultrafiltration“, Langmuir, 10,

4710-4720 (1994).

* S. Bhattacharjee, A. Sharma and P. K. Bhattacharya,

“Estimation and influence of long range solute-membrane

interactions in ultrafiltration“, Ind. Eng. Chem.

Res., 35(9), 3108-3121 (1996). [Invited paper for the special issue in honour of Prof.

E. Ruckenstein].

-

Mass Transfer Coefficient with Suction

Sherwood number relations for the prediction of mass

transfer coefficient, including the effect of suction,

have been developed from first principles]. The proposed

relations predict the permeate flux in RO and UF in an

excellent manner. For other effluents, some empirical

equations have also been developed.

* S. De and P. K. Bhattacharya, “Mass transfer

coefficient with suction including property variations

in applications of cross-flow ultrafiltration“, Separ.Purif. Technol., 16, 61-73 (1999).

* S. De and P. K. Bhattacharya, “Prediction of mass

transfer coefficient with suction in the applications of

reverse osmosis and ultrafiltration“, J. Membrane Sci.,

128, 119-131 (1997).

-

Generalized Integral & Similarity

Solutions for Concentration Profiles

In this exciting method, one has to solve only two

ordinary differential equations and one non-linear

algebraic equation, compared to solving around 700

coupled ordinary differential equations simultaneously

in the detailed numerical solution. Still accuracy and

generality of the problem are fully retained. The model

can predict flux decline over time (for an unstirred) or

over channel length (for a steady cross-flow system) as

well as of the permeate concentration with time or

channel length, if operating conditions are known.

* S. De, S. Bhattacharjee, A. Sharma and P. K.

Bhattacharya, “Generalized integral and similarity

solutions for concentration profiles for osmotic

pressure controlled ultrafiltration“, J. Membrane,

Sci., 130, 99-121 (1997).

Back |